Gear metering Pumps

Home » Capabilities Overview » Sealant Application System » Glass Gluing System » Gear metering Pumps

Patvin Engineering is the leading supplier of gear metering pumps with over three decades of expertise.

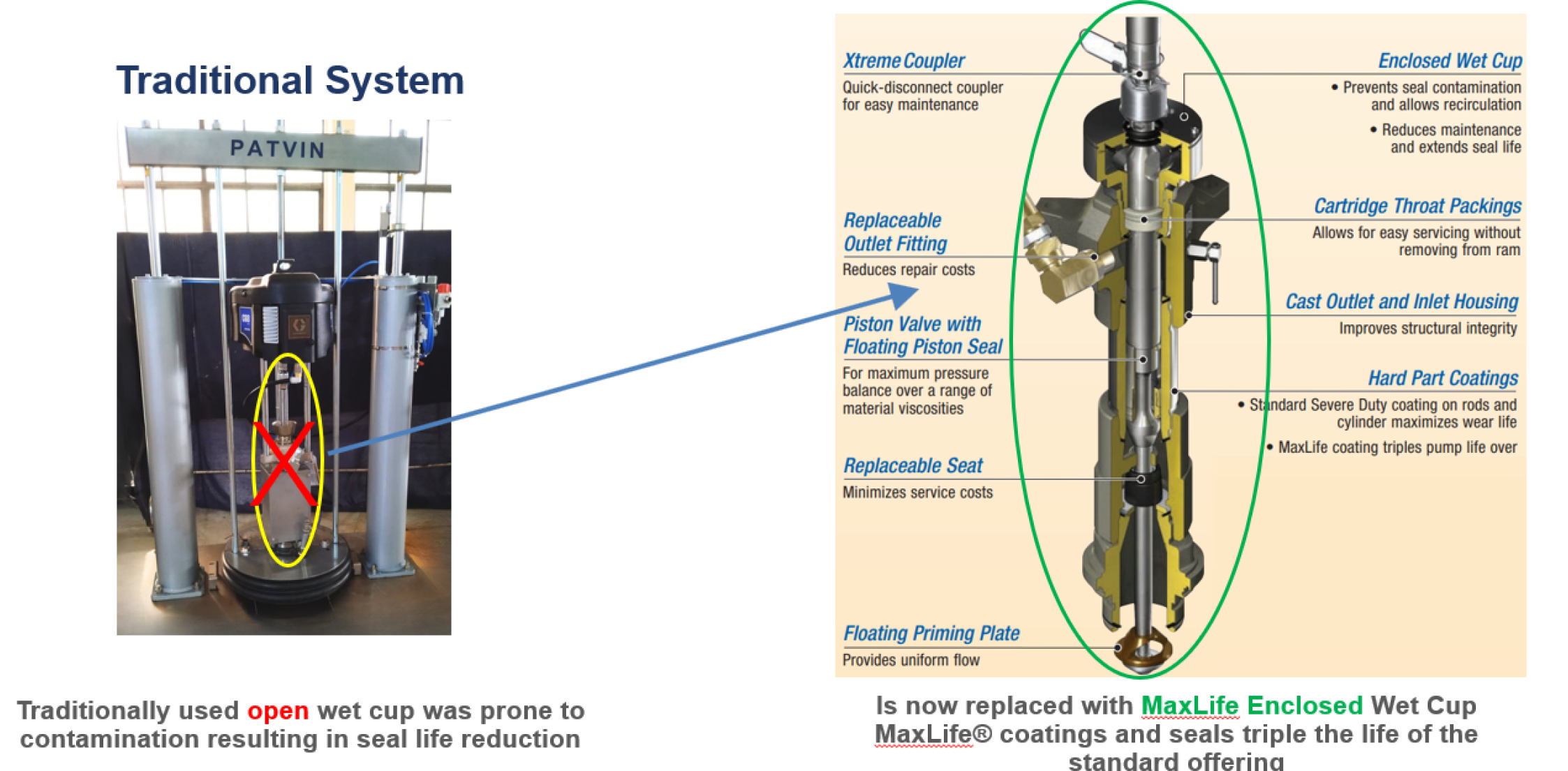

Our Gear Metering Pump System is equipped with a PLC and Servo drive, ensuring a continuous flow of sealant without any interruptions. This metering system provides accurate metering and complete control, producing a smooth and consistent bead every time.

Additionally, the pressure sensors installed at the inlet and outlet monitor pressure levels closely while being interlocked to prevent any dry running of the pump.

Metering Pumps for Adhesives & Sealants

Why Gear Metering Pumps?

- Trapped air removed by vacuuming reducing material wastage up to 50%

- Non-stick coating on follower plate to prevent material adhesion

- No material wastage

- Ease of cleaning

- Avoids material lumps inside system

- Addition of pump stroke sensor to avoid air entrapment and monitor healthy running of Pump

FAQs

Gear metering pumps are devices that are designed to deliver a specific volume of liquid with each rotation. They are crucial for accurate dosing in various industrial processes using interlocking gears to push fluid through pumps to ensure a steady and accurate flow.

Gear metering pumps when used for coating applications ensures even distribution of coatings providing consistent and high-quality finishes, reducing waste. Its design allows it to handle different viscosities while maintaining a pulse-free flow.

A gear metering pump can be used for adhesive applications providing accurate dosing of adhesive materials. They are designed to provide accurate flow rates, ensuring that adhesives are applied consistently, reducing waste and improving production efficiency.

A metering system for sealants accurately dispenses sealants reducing waste and improving its application efficiency which is vital in automotive assembly. They are particularly effective in managing multiple sealant types with varying viscosities.

1. When selecting a gear metering system consider factors such as,

- Fluid viscosity,

- Required flow rate

- Application type

- Can handle the specific materials