Liquid Gasketing

Home » Capabilities Overview » Sealant Application System » Liquid Gasketing

Liquid Gasketing is a critical process in many industries, including automotive, electronics and machinery. This method involves using a liquid sealant to create a seal that seals the joints and prevents the leakage of liquids or gases. Patvin’s state-of-the-art robotic solutions demonstrate these benefits by providing the industry with reliable and efficient sealing systems.

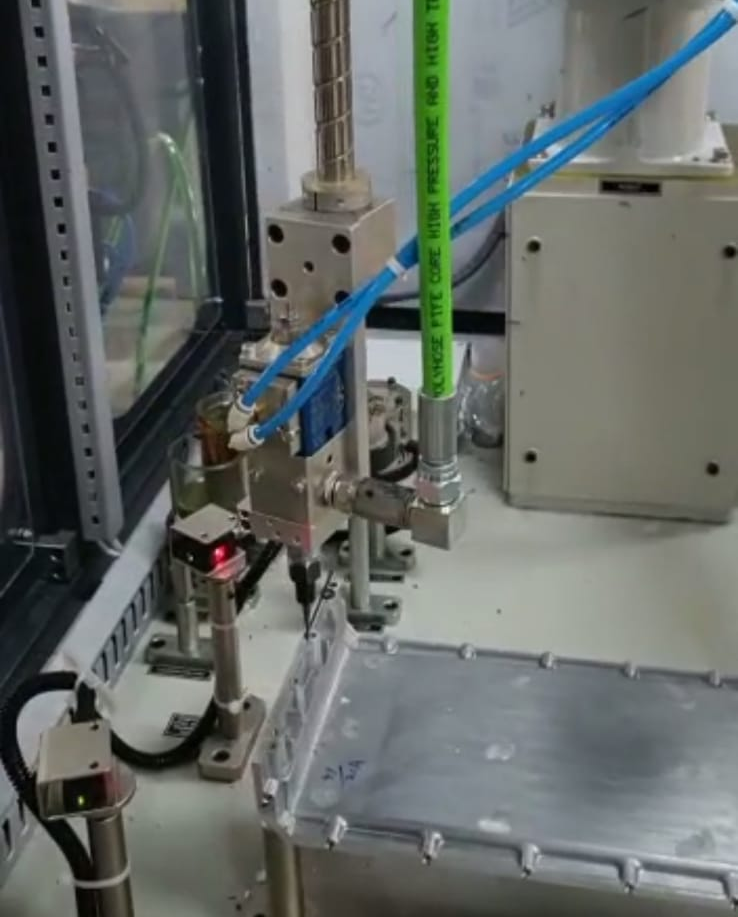

Unlike manual methods, robotic gasketing applications are programmed to apply the sealant with high to ensure uniformity and consistency of all sealants. Patvin’s robotic & manual gasketing applications use advanced sensors and control systems to monitor the application process in real-time.

This technology enables precise control of the quantity and placement of packets, ensuring that each guard meets strict quality standards. The result is a reliable and durable seal that improves overall product performance and longevity.

Liquid Gasketing Application:

Liquid Gasketing offer significant manufacturing efficiencies in automotive applications such as noise reduction for vehicle transmissions, oil pans, window seals, front engine plates, camshaft covers, and more. Using 1K and 2K Dispensing Devices in Combination with robotic automation play an important role in liquid seal applications.

Manual & Robotic Gasketing applications

Benefits of Patvin’s Liquid Gasketing System:

Efficiency and Speed:

Efficiency is another important advantage of liquid boot compression. Manual gasketing application can be slow and labor intensive, leading to production line bottlenecks. Robots, on the other hand, can work continuously without fatigue, which greatly increases production speed. They can also quickly switch between different tasks and applications, increasing productivity.

Seamless Integration:

Patvin robotic gasketing systems are designed to integrate seamlessly into existing production lines, optimizing the compact process. Robots can be programmed to handle a variety of sealing materials and applications, making them versatile tools in manufacturing. This flexibility allows manufacturers to adapt to changing production needs and maintain high efficiency.

Waste reduction:

Waste reduction is a critical issue in industry, both economically and environmentally. Manual compaction methods often result in overuse of material resulting from spreading or spillage. However, robotic gasketing application systems are designed to optimize material use by using the right amount of sealant for each task.

Patvin’s robotic solutions for liquid sealants include intelligent dosing systems that regulate sealant flow and minimize waste. This not only reduces material costs, but also reduces the environmental impact of the production process.

Quality and reliability:

The consistent quality of liquid seal robotic seals means better reliability of the final product. A uniform and precisely positioned guard provides a better seal, which is essential in applications where leakage prevention is critical. This is particularly important in industries such as automotive and electronics, where even small leaks can cause significant problems such as component failure and safety hazards.

Patvin’s robotic liquid gasketing application ensures that each seal is used exactly to specification, improving overall product quality and reliability. This precision reduces the need for rework and repair, saving time and resources in the long run.

By adopting robotic liquid compactors, manufacturers can achieve higher quality products, lower production costs and more sustainable operations. The future of liquid seals lies in automation, and Patvin is at the forefront of this technological development, offering customized, high-performance solutions to meet the diverse needs of modern manufacturing..

FAQs

Liquid gasketing refers to a sealing solution applied in liquid form to create a flexible, durable seal between surfaces. This method allows for precise application and can conform to complex shapes, making it ideal for various industrial applications. Patvin Engineering provides advanced liquid gasketing solutions for various applications.

Manual gasketing application involves using tools to apply sealants precisely. Manual gasketing application is perfect for projects requiring flexibility or precision. It allows the operator to apply the liquid sealant directly to specific areas, ensuring a strong seal for various parts.

Robotic gasketing applications are possible. It ensures consistent and efficient sealing for large-scale operations. Using a seal for robotics enhances the performance and longevity of robotic systems. Liquid gasketing forms a durable barrier, preventing contamination and extending the life of robotic equipment in demanding environments. Patvin Engineering offers reliable seals for robotics.

Applying sealants with cobots improves precision and reduces human error. Cobots can precisely dispense liquid gasket materials, ensuring accurate application and reducing the risk of human error. This leads to better sealing performance in various applications. They assist in precise applications, ensuring a consistent seal every time, making them a valuable tool for both small and large projects.

Liquid Gasketing is versatile and used in various industries, such as:

- Automotive

- Electronics

- Industrial machinery

- Aerospace

- Manufacturing.

These industries rely on effective sealing methods to ensure product integrity and performance in challenging conditions.