Thermal Management

Home » Capabilities Overview » EV BATTERY » Thermal Management

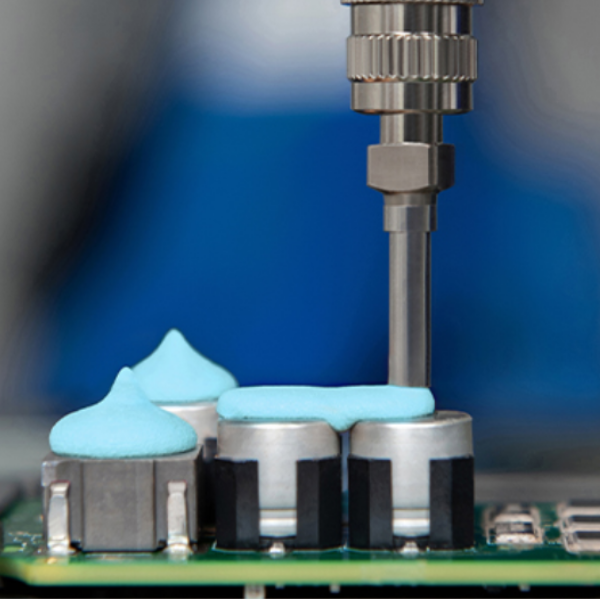

Thermal interface materials used in gap filling applications are critical to overall battery performance and safety. When dispensed correctly, the gap fillers dissipate heat away from the battery, improving battery speed, longevity and decreasing the likelihood of thermal events.

However, pumping and dispensing thermal interface material (TIM) brings many challenges to electric vehicle (EV) battery assembly lines. Highly abrasive and low viscosity in nature, the gap filler can quickly wear out equipment. TIM also needs unique attention to pressurization to ensure optimal heat transfer.

To withstand this tough material, manufacturers should consider robust equipment that allows for high flow, precise metering and dispense.

Advantages:

- Critical to overall battery performance and safety

- Dissipate heat away from the battery

- Improves battery speed & longevity

- Decreases the likelihood of any thermal events

Patvin Engineering Solutions:

FAQs

Thermal management in electrical vehicles is about controlling the temperature of battery systems ensuring the battery operates within temperature ranges, enhancing performances and safety, thus preventing overheating and prolonging battery life by using materials like thermal interface materials and gap fillers.

A battery gap filler refers to a thermal interface material that is used to fill spaces between battery components improving heat transfer by eliminating air gaps enhancing overall thermal management of the EV battery and ensuring efficient operation during charging and discharging.

A gap filler conforms to the surfaces of battery cells and heat sinks filling the microscopic gaps for better thermal conductivity resulting in consistent heat distribution and prevention of overheating.

Using a gap filler for batteries provides several benefits:

- Improved Thermal Management

- Prevention of Hot Spots

- Vibration Damping

- Moisture and Contaminant Protection

- Customization and Versatility

- Reduced Manufacturing Complexity

- Enhanced Battery Lifespan

Gap filling applications improve battery performance by ensuring effective heat dissipation, reducing the risk of hot spots and maintaining consistent temperature across the battery pack thus leading to improved efficiency, faster charging times, and longer battery life.

You can customize thermal management solutions for gap fillers and thermal interfaces based on specific requirements. Patvin Engineering provides altering thermal management solutions to ensure optimal performance and safety for different battery designs and applications. Get in touch with us for more information!