Structural Bonding Solutions

Home » Capabilities Overview » EV BATTERY » Structural Bonding Solutions

Patvin Engineering is the leading supplier of Structural Bonding Solutions for EV Batteries with more than thirty years of experience.

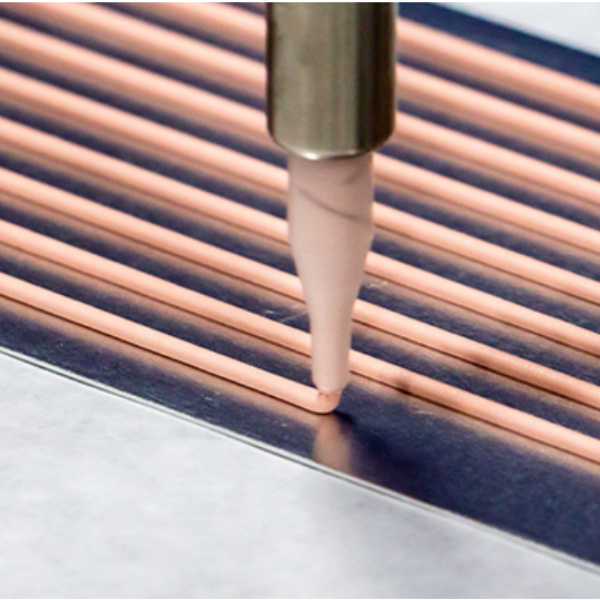

Using adhesives for structural bonding methods help make a battery lightweight, while adding strength and rigidity. Typically, a one or two component epoxy adhesive is dispensed in a bead shape to bond two pieces of a battery pack together.

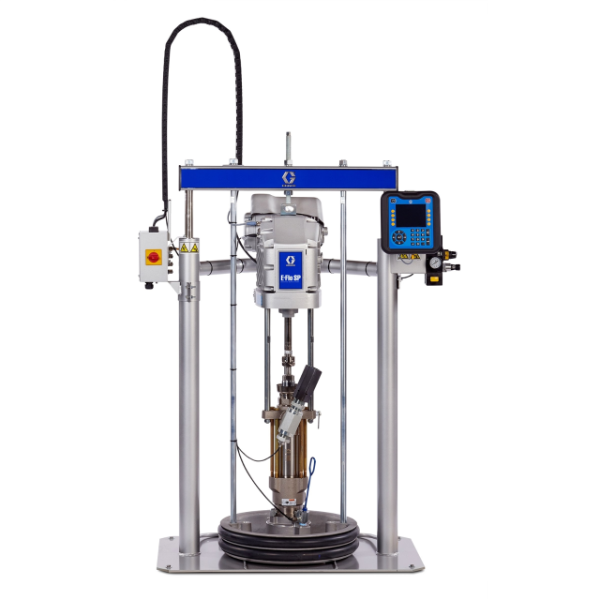

Precision and accuracy are important to proper bonding and efficient material use. It’s best to use automated adhesive dispensing systems for structural bonding. They offer strong control over materials and help apply adhesives with high precision.

Advantages of structural bonding:

- Helps make a battery lightweight

- Offers extra strength and rigidity to the battery pack

- Vibration and Fatigue Resistant

Patvin solutions for structural bonding

FAQs

Structural bonding refers to the process of using adhesives to join two or more substrates together. Unlike traditional methods like welding or riveting, structural bonding uses bonding solutions to create strong, lasting connections. It involves using structural adhesives that can bear loads and maintain the integrity of the joined surfaces. This technique is essential in industries where reliable bonding solutions are crucial. Structural bonding and adhesives ensure the integrity and strength of the assembled parts, making them vital for many applications.

Structural bonding has multiple types depending on their material and applications, such as:

- Epoxy Adhesives

- Acrylic Adhesives

- Polyurethane Adhesives

- Methyl Methacrylate Adhesives

- UV-Curable Adhesives

- Silicone Adhesives

- Cyanoacrylate Adhesives

Each bonding solution is designed for specific applications.

Benefits for use of Structural Bonding can be stated as:

- Strength: Structural adhesives can form bonds stronger than many mechanical fasteners.

- Weight Reduction: Using adhesives instead of metal fasteners can reduce the weight of structures.

- Versatility: Structural adhesives can bond a variety of materials, including metals, plastics, and composites.

- Stress Distribution: Adhesives spread stress over a larger area compared to traditional fasteners, reducing the risk of localized failure.

- Durability: Properly applied structural adhesives resist environmental factors such as temperature changes and chemicals, ensuring long-lasting bonds

Structural bonding is widely used in several fields such as:

- Construction

- Automotive Industry

- Aerospace

- Electronics

- Marine

- Renewable Energy

- Medical Devices

Advantages of Structural Bonding

- Strong Bonds

- Lightweight

- Even Stress Distribution

- Material Versatility

- Aesthetic Finish

- Corrosion Resistance

- Cost-Effectiveness

- Quick Assembly

Disadvantages of Structural Bonding

- Surface Preparation

- Cure Time

- Environmental Sensitivity

- Difficulty in Disassembly

- Specialized Equipment

- Process Control

- Limited Visibility

Few examples for structural bonding are:

- Flemish bond

- English Bond

- Stone Masonry

- To join metal panels in car manufacturing

- Aircraft components