Cavity Wax Application

Home » Capabilities Overview » CAVITY WAX APPLICATION

Patvin is a leading manufacturer and supplier based in India with over two decades of expertise. We provide a comprehensive turnkey solution for cavity wax application systems such as Manual and Automatic Wax Feed System, and Wax nozzles.

What is Cavity Wax Application?

A process where a special type of wax is applied in the hidden cavity-prone areas for a protective coating is called as cavity wax application. This procedure is mainly used in industries to avoid rust and corrosion and to increase the life span of the product. We can get end-to-end cavity protection solutions with optimum utilization of cavity wax.

In automotive manufacturing, cavities are coated with wax to effectively protect the car body from corrosion. Cavity wax provides a barrier to corrosive media such as salt, dirt, dust and humidity.

Features of Wax Feed Systems:

- This wax panel supply system is designed to achieve predefined wax dispense at an application Temperature set value of +/- 2 Deg C. A variance above +/- 2 Deg C will call for a Production Halt /warning.

- The system mainly comprises a jacketed tank, a pneumatic pump, and a cartridge filter.

- The system incorporates a PLC-based master control panel which accepts temperature input from PT-100 installed in the wax line & controls Hot/Cold water.

- Temperature-conditioned wax is circulated throughout the system via high-pressure SS 304 pipes. The piping network is designed to ensure a smooth flow of material with the least/No retention areas.

- All Wax Pipes are Insulated using ARMAFLEX Insulation of Appropriate thickness to maintain the desired operating temperatures.

- A flow meter provides feedback on the precise volume to be dispensed from the wax gun. This reduces the required shot volume and cuts material, cleaning, and disposal costs.

Cavity Wax Feed Systems Offered by Patvin:

Manual Cavity wax application:

In our manual wax feed system, an encoding spray gun is used to manually coat hollow spaces with liquid-conserving wax. All components feature exceptional precision and reliability in continuous operation and can achieve perfect coating results.

By actuating the trigger, an electrical pulse is generated and transmitted to the connected control cabinet. The gun has encoder housing which detects magnetically coded nozzles & provides a signal to PLC to activate a predefined program.

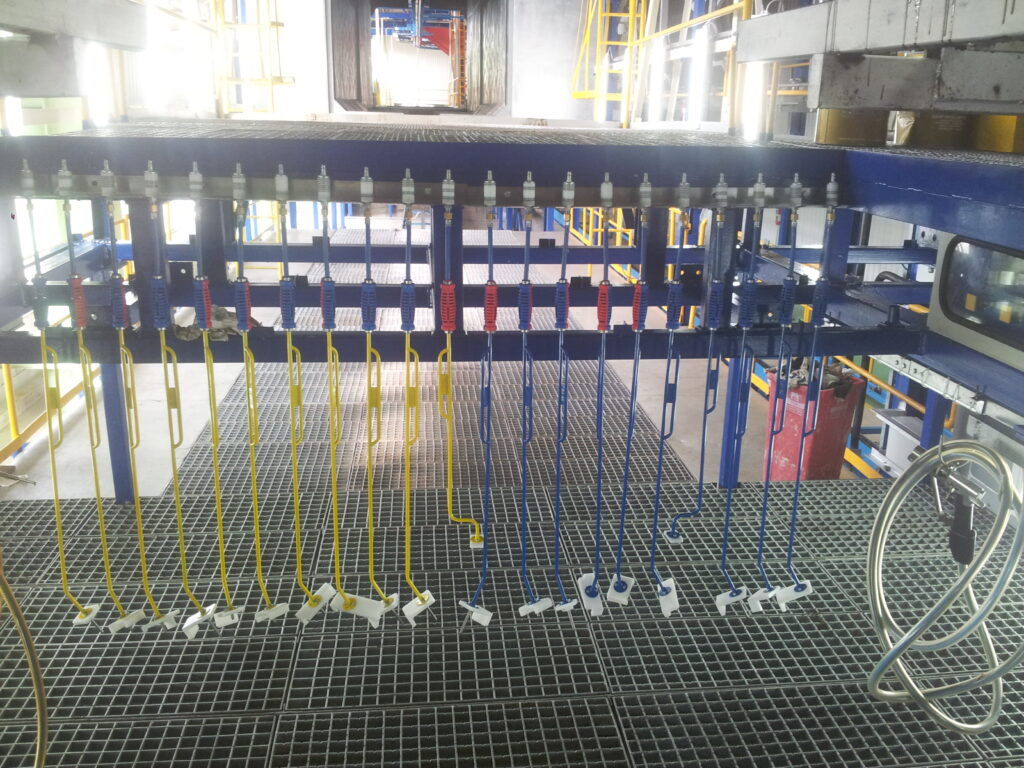

Automatic Cavity Wax application:

Our automatic wax feed system has fixed nozzles reduces labor requirements and speeds up the cycle time. This technology delivers maximum performance and increased efficiency. The cycle time is approximately 50 seconds.

Why Use Cavity Wax Solution?

Automobiles experience very harsh environmental conditions and most automotive manufacturers recommend the use of Cavity Wax to prevent corrosion when repairing or replacing panels. This practice helps safeguard the repair structural components that have been welded during the repair process are of special concern as it relates to corrosion for obvious reasons.

Areas of application: For long-lasting protection of areas in vehicle body cavities prone to corrosion. Used for subsequent treatment of existing seals and for restoring corrosion protection after an accident repair. It protects car bodies from corrosion caused by salt, dirt, dust, and humidity, offering comprehensive wax utilization.

WAX NOZZLE

Patvin offers various in-house wax nozzles such as pokayoke nozzles. These Special Wax Nozzles are designed as per contour/cavity to achieve maximum coverage of wax in the box sections of the vehicles. The in-house development and manufacture of wax nozzles allow us to achieve maximum quality for openings and geometries.

FAQs

Cavity wax can be used to provide a barrier against salt, dirt, and moisture in these areas as well as seal the welds and seams that rust proof paint or coating can't reach.

There are various techniques used for Cavity Wax Application such as - Spray Application, Injection Methods, Brushing, or a combination of them.

Patvin is a leader when it comes to providing wax feed systems. Over the decades we have mastered the art and can exactly know what will suit the best of our clients.

Patvin's turnkey solution has a Wax Feed System, precise Pipe Network, and manual/automated application methods for effective cavity wax coating.

Our Happy Clients