Glass Gluing System

Home » Capabilities Overview » Sealant Application System » Glass Gluing System

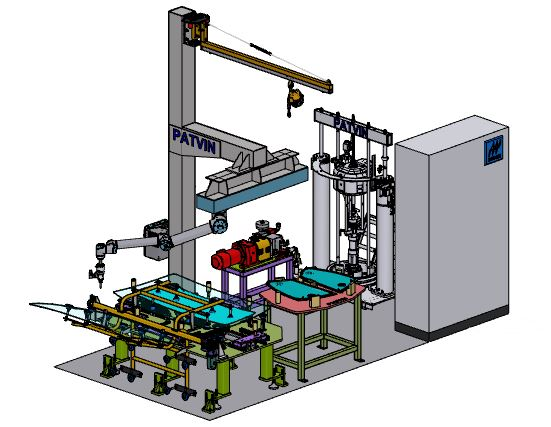

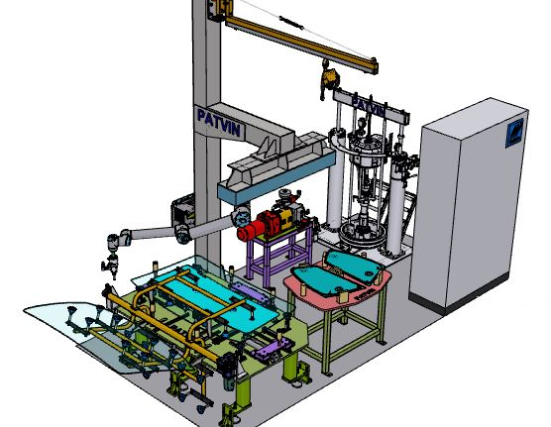

Glass Gluing System for General Assembly

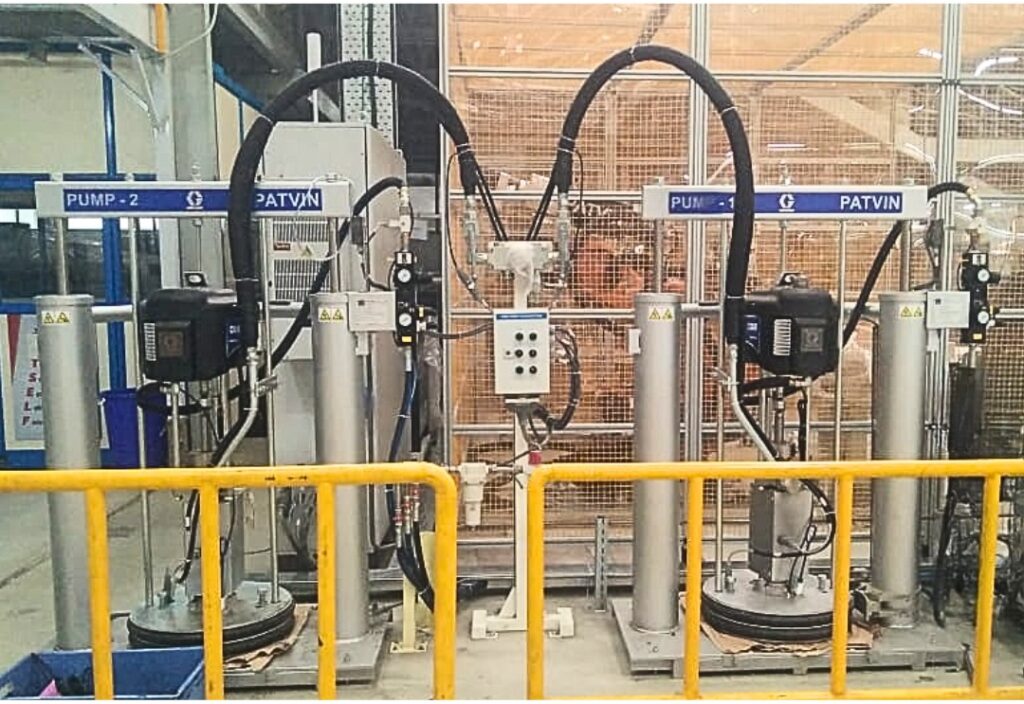

Patvin Engineering is the leading supplier of Glass Gluing System with over three decades of expertise.

Glass bonding application is another important adhesive application in the automotive industry. Polyurethane is commonly called urethane. This is an adhesive specially developed for the sealing and bonding of windshields, side windows, quarter windows and rear windows in the automotive industry.

Glass Bonding System Components

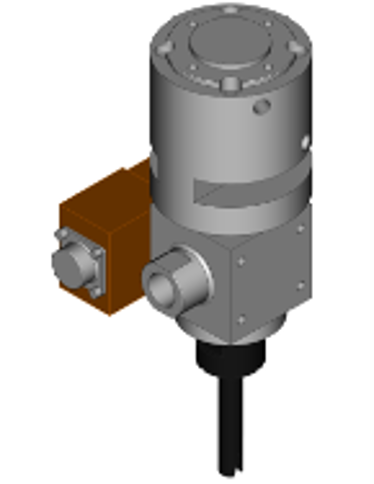

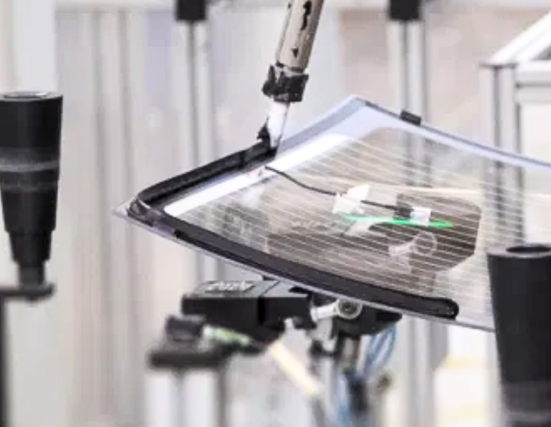

Dispense Head

- It comprises of dispense gun with Rotating nozzle head.

- It has been provided for integrating the Robot 6th Axis for the rotation of gluing nozzle for ease of robot programming.

Heated Hose

- Insulated Stainless Steel Braided PTFE Warm Melt/Hot Melt Heated Hose are designed to give accurate and uniform temperature conditioning for your Sealant and Adhesive applications.

- Use these hoses to keep your material at the ideal temperature for the best possible dispense quality.

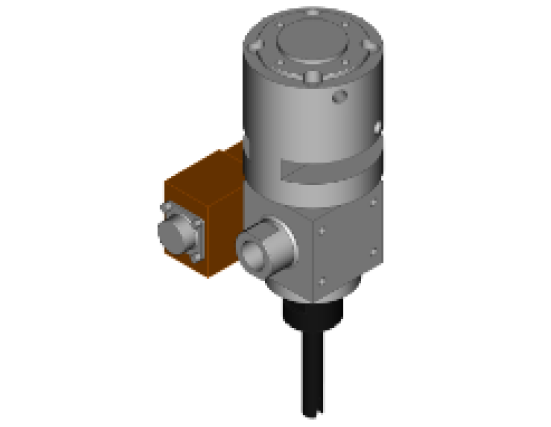

Gear metering Pump

Our Gear Metering System is equipped with a PLC and Servo drive, ensuring a continuous flow of sealant without any interruptions. This system provides accurate metering and complete control, producing a smooth and consistent bead every time. Additionally, the pressure sensors installed at the inlet and outlet monitor pressure levels closely while being interlocked to prevent any dry running of the pump. Click here to learn more.

Patvin's Glass Bonding Applications

FAQs

A glass bonding system is a machine that uses polyurethane adhesives to bond glass together commonly used in automotive applications. The system typically includes a dispense head, heated hoses, and a gear metering pump.

The dispense head applies the adhesive to the glass, the heated hoses keep the adhesive at the correct temperature, and the gear metering pump ensures that the adhesive is dispensed accurately and consistently. Learn more.

These gluing systems are used in a variety of automotive glass bonding applications, including bonding windshields, backlights, and side windows to car bodies. They can also be used in other applications where strong, durable bonds between glass components are required.

Glass bonding systems offer several benefits over traditional methods of bonding glass, such as using sealants or tapes. These benefits include: Accuracy and consistency, Speed, Strength.

Glass gluing systems work in a four step process:

- The adhesive is loaded into the system's reservoir.

- The adhesive is heated to the correct temperature using heated hoses.

- The adhesive is dispensed from the dispense head onto the glass.

- The glass components are pressed together to form a bond.

There are a few things to consider while choosing glass to glass bonding system , such as:

- The type of adhesive that will be used

- The size and shape of the glass components that will be bonded

- The production speed requirements

- Project Type & Budget