Body Shop

Home » Capabilities Overview » Sealant Application System » BODY SHOP

With today’s advanced vehicle designs, where durability, performance, and safety are vital, OEMs and tiered suppliers are relying on Patvin dispensing solutions for Body-in-White (BIW) applications.

Sealants and adhesives are paramount as automotive manufacturing calls for a low-weight and improved structural integrity. Patvin dispensing systems provide an accurate material dispense in simplified systems to allow for greater design flexibility and reduced production costs.

EFLO IQ

The E-Flo iQ is a single component tank-to-tip solution that provides your automatic applications with an intelligent metering system. With its electric servo-driven motor, the E-Flo iQ will meter directly from the drum and keeps an optimal flow control with assured performance without the need of external dosing systems

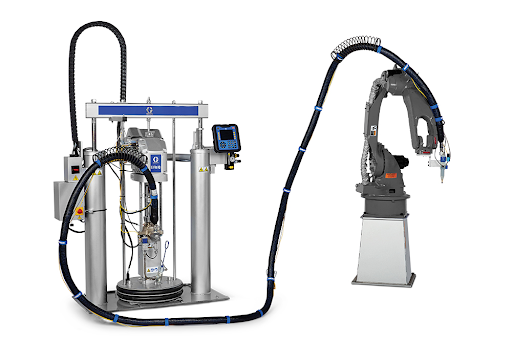

RAM PUMP 20/200

Patvin Supply Systems reliably deliver one-component sealants, adhesives and other medium to high-viscosity materials from pails or drums to metering and dispensing systems.

Bulk unloaders for ambient sealants, adhesives and other medium to high-viscosity materials.

- For large drums up to 200 liter (55 gal)

- Graco D200 – For high-volume in-plant applications

- Industry-first controls give you immediate and important information at the touch of a button

- Quick placement of drum

- Platen wipers can be replaced in seconds

- Pump’s quick-disconnect coupler, turnbuckle mount and pump cartridge packings let you service the pump without removing it from the ram

- High-quality, durable parts reduce maintenance time, maximize uptime

PRECISION CONTINUOUS FLOW METERING & DISPENSING SYSTEMS(PCF)

Our PCF Metering System provides a precise, continuous flow for sealant and adhesive dispensing. This closed-loop, continuous-flow metering and dispense system offers high accuracy without costly reload times. With PCF material is continuously metered and controlled, providing accurate control with no limitation on shot size.

- Provides consistent, continuous flow – no worry of slow shot meter refill times or the expense of more complicated mechanical solutions

- Intuitive user interface and control options

- Self-diagnostics allow for predictive and preventive maintenance strategies – improving process availability

- Multiple applicator capabilities – lets you program parameters for up to 16 different applicators

- Superior flow control saves material – less material waste

SWIRL

PRECISION SWIRL

Applies a uniform, circular loop pattern with clean edges and no mess. PrecisionSwirl features adjustable rotational speed, stand-off distance and flow rate for greater control and for better penetration on irregular shaped parts. It is compatible with most sealants including expandable sealers, heat cure epoxy and PVC plastisol.

TEMPERATURE CONDITIONING UNIT

- Air cooled water chiller with integrated heating capability for the water circuit

- Mobile unit for individual machines or multi-machine applications

- For water temperatures from +10°C up to +40°C, at ambient temperatures up to +45°C

- Suitable for high ambient air and tropical installations

Electronic flow control with digital display

No unnecessary water consumption due to a closed water circuit

Electronic flow control with digital display

Operating principle

The unit is equipped with a corrosion free water tank with a content of approx. 25 litres. The cooling compressor cools the water content to the required temperature. The resultant heat leaves the unit through the cover and the side panels. Should the water temperature be too low, the heating element will be activated automatically.

- Self-optimizing microprocessor controller with digital display of the set and actual temperature. With high precision regulation in 1/10° range; can be adjusted to read °C or °F.

- Digital flow indication with control of the minimum flow.

- All components in contact with water are made of corrosion resistant stainless steel or bronze.

- Long life expectancy due to the electronic control of the compressors operating time.

- If the water in the system does not reach the required temperature, the built-in heating will be activated automatically.

- Automatic or manual water refill.

- Automatic level control with prewarning at low water level.

- Horn in case of failure.

- All failures are visually indicated.

- Unit on castors.

Electronic temperature controller operating principle

The unit is equipped with a corrosion free water tank with a content of approx. 25 litres. The cooling compressor cools the water content to the required temperature. The resultant heat leaves the unit through the cover and the side panels. Should the water temperature be too low, the heating element will be activated automatically.

- Self-optimizing microprocessor controller with digital display of the set and actual temperature. With high precision regulation in 1/10° range; can be adjusted to read °C or °F.

- Digital flow indication with control of the minimum flow.

- All components in contact with water are made of corrosion resistant stainless steel or bronze.

- Long life expectancy due to the electronic control of the compressors operating time.

- If the water in the system does not reach the required temperature, the built-in heating will be activated automatically.

- Automatic or manual water refill.

- Automatic level control with pre warning at low water level.

- Horn in case of failure.

- All failures are visually indicated.

- Unit on castors.

GRACO RELIABILITY

- Applies a uniform, circular loop pattern with clean edges and no mess

- Dispenses open or closed, wide or narrow pattern beads for a variety of applications

- Simplifies robotics programming for directional changes

- An orbiting nozzle allows you to apply material on vertical and horizontal surfaces

- Reduces manual touch-up, masking and rework

APPLICATOR ROBOTIC

SWITCH 3D GUN

Switch 3D Gun is a lightweight, high-pressure rotary applicator designed for automotive seam sealing, underbody coating and underbody sealing applications.

The Graco Switch 3D Gun is a sealant and adhesive applicator designed with a swiveling head and three individually operated nozzles. These unique features provide increased spray efficiency, flexibility and versatility for most types of single component adhesives and sealants with medium to high viscosities.

Switch 3D Sealant Gun Benefits

- Increase your productivity

- Apply a single or two independent materials with the same unit

- Easily integrate with robots

- Versatile and easy to use in confined spaces

- Eliminates twining hoses

- Ability to circulate material

- Dispense material at difficult angles and improve dispense efficiency

Optional Features Include:

- Mounted material pressure monitor

- Temperature sensor in the material inlet

- Insulated central body for improved temperature control

- Nozzles can be configured to different angles and slot directions

- Short inlet housing

BINKS SEALANT AND ADHESIVE EQUIPMENT

Extremely accurate dispensing solutions help customers to increase Overall Equipment Effectiveness (OEE) by improving quality and reducing downtime while lowering installation and maintenance costs.

Innovative products provide superior dispense accuracy — providing process reliability, repeatability and better control of the dispense processes.

Individual components and turnkey systems are available for a wide range of dispensing applications. These systems can be easily integrated into most manufacturing protocols for cooperation with robots and other process controls.

PRODUCTS

Supply pumps, controls and applicators can be easily integrated into systems to increase performance, reliability and efficiency.

TURNKEY DISPENSING SYSTEMS

Systems and support for a wide variety of sealant and adhesive dispensing industries.

HANDHELD GRACO

Welcome to the newest line of Graco’s handheld airless sprayers. With the addition of the new XForce HD heavy-duty cordless sprayer, Graco’s handheld sprayers cover all of your painting applications from architectural painting to fine finishing to protective coating and corrosion control. All Graco handheld sprayers are designed with ProSpray Technology, which includes Graco’s proven piston pump design that delivers a professional finish – in the palm of your hand! Using lithium-ion batteries, all Graco cordless handheld sprayers give you the ultimate power and freedom to spray wherever you want. No matter what your small job or touch-up work is, Patvin has a solution for you!

Body Shop:

- Mastic Sealant Application

- Hemming adhesive application

- Structural adhesive application

- Multidrop sealant system

- Antiflutter sealant system

- Mastic Sealant Application

In automotive manufacturing and repair, mastic sealants are applied to seams, joints, and panels, reducing noise and vibration and preventing water and dust infiltration. - Structural adhesive application

Increasing demand for vehicle weight reduction, enhanced safety, and increased reliability, structural adhesive utilization in automotive body-in-white (BIW) applications has been growing. High-strength adhesives paired with mechanical joining methods can improve the stiffness, strength, and fatigue life of automobile structures. Other advantages, such as lower noise and vibration levels, can be acquired in addition to more strong, stable structures. - Crash Sealer Application

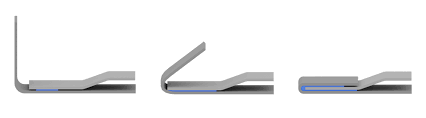

Cutting vehicle weight without sacrificing safety is a major engineering challenge. As a result, crash safety bonding is now the most significant bonding process in the car body structure (as it directly impacts the performance of the car body structure sections in the event of a crash). - Anti flutter sealant application

The function of an anti-flutter application is to reduce or eliminate any “fluttering” or vibration of the outer and inner panels relative to each other. This application is more commonly used on horizontal closure panels such as hoods and deck lids ̶ and to a lesser degree on vertical panels, like doors and lift gates. - Hem flange bonding

Patvin offers a broad range of applications for hem flange bonding. Although typically used with hang-on parts, the inclusion of glass beads also makes Patvin application suitable for use in body structures. The advantage of the glass beads includes “zero-gap” avoidance, which leads to better adhesion, mechanical performance, aging and corrosion properties. Depending on the customer requirements and processes, glass spheres of different sizes can be integrated.

Sealant pump

Body shop sealer feeding system

Body shop sealant

Bodyshop sealer automatic application

Antiflutter material

Automatic precision shot meter dispense system

Robotic precision continuous flow metering and dispense system

Hem flange bonding

Supply pumps for sealant and adhesive

FAQs

A sealant application system is used to apply sealants effectively within body shops, ensuring precise and uniform application of materials, thus helping improve the quality of repairs, reducing waste during the sealing process.

A sealant supply system works by delivering materials directly to application tools, maintaining consistent pressure and flow thus ensuring the right amount of sealant is available when needed.

Mastic sealant in automotive applications gives flexibility and durability for sealing joints and seams, clinging well to multiple surfaces, thus making it ideal for body shop repairs, reducing noise and vibration in vehicles.

Automated application sealants are used with robotic systems in body shops ensuring consistent application and high-quality finishes. Thus helping streamline the repair process, saving time and labor costs while improving accuracy.