Battery pack sealing

Home » Capabilities Overview » EV BATTERY » Battery pack sealing

Achieving a quality seal is critical for the performance, longevity, and protecting components of the battery from water and other harsh environmental conditions.

Battery pack seals or gaskets must meet design and regulatory enclosure standards. For example, an IP68 rating means that the seal will protect against water intrusions, corrosion, and outside contaminants.

Types of Pack Seal:

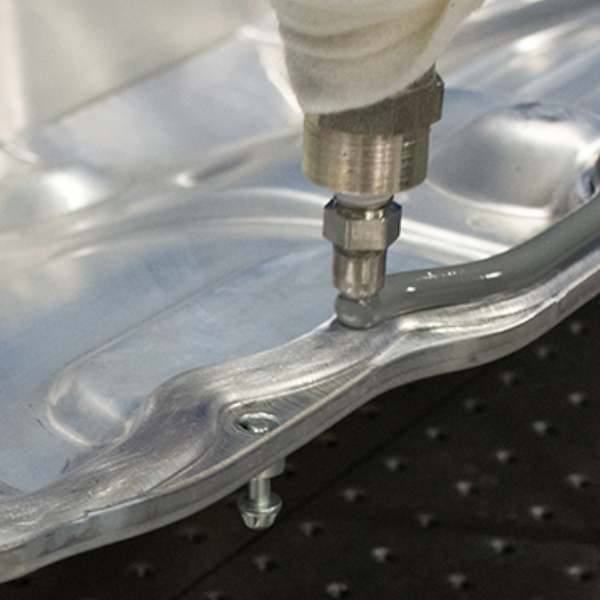

Manufacturers meet these standards by robotically dispensing a bead of one or two component material around the perimeter of the battery pack in one of two ways:

Cure in place gasketing (CIPG): The dispensed material cures before assembly, creating a compression gasket in the pack seal joint.

Form in place gasketing (FIPG): The material is dispensed and assembled immediately, allowing the material to cure over time.

To ensure a durable, reliable seal, gasketing must be clean, precise and repeatable. Bead placement, flow rate, volume of material dispensed, and mix ratios for two component materials are critical.

Customer advantage of Battery Pack Sealing:

- Critical for the performance, longevity, and overall protection

- Protects against water intrusions, corrosion, & outside contamin

Here are EV Battery Seal solutions offered by Patvin:

FAQs

Battery pack sealing is the process of securely enclosing battery cells to protect them from moisture, dust, and external damage. At Patvin Engineering, we provide effective battery sealing solutions that enhance the safety and longevity of your batteries.

Patvin Engineering offers a range of battery sealing solutions, including advanced materials and techniques for optimal pack seal integrity. Our services ensure long-term protection and high performance that meet industry standards.

Effective battery pack sealing is crucial for preventing leaks and ensuring safety against harsh environmental conditions. A good seal protects against electrolyte leaks and maintains the performance of the battery, especially in electric vehicles where battery reliability is essential.

Our equipment refurbishment services include improving existing battery sealing systems. We enhance the seal quality to ensure better protection and performance, extending the life of your battery packs.

Yes, we can customize our battery sealing solutions for different battery types, including EV battery seals to meet your specific requirements. Our team at Patvin Engineering will work with you to develop the best solution.

Here in Patvin Engineering, we specialize in offering top-quality battery sealing solutions. We ensure your battery packs are securely sealed for optimal performance.